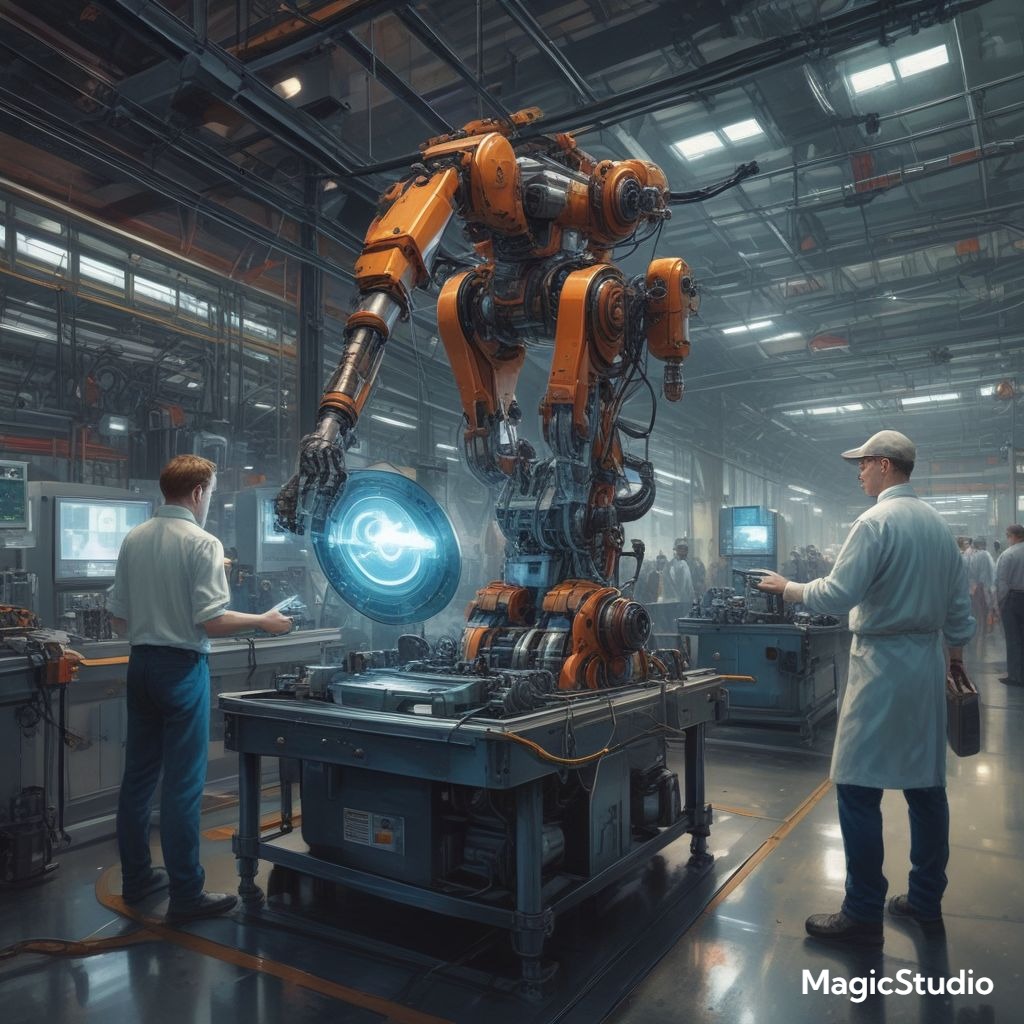

As industries continue to evolve, automation and robotics are becoming pivotal in shaping the future of manufacturing. Smart factories, which rely on these advanced technologies, are transforming the way products are designed, produced, and delivered. Automation is streamlining operations, reducing costs, and enhancing overall efficiency, while robotics is enabling precision and speed in manufacturing processes that were previously unimaginable.

Automation has been a key driver of productivity in the manufacturing industry. With the use of automated systems, companies are able to reduce human errors, improve safety, and optimize production times. Machines equipped with sensors, artificial intelligence (AI), and machine learning are capable of performing repetitive tasks with high accuracy, ensuring quality and consistency.

In smart factories, automation is integrated with digital technologies like the Internet of Things (IoT) and big data analytics. IoT devices gather real-time data from machines, which is then analyzed to optimize performance, predict maintenance needs, and prevent downtime. This predictive maintenance capability can save companies significant costs by reducing equipment failure and increasing operational efficiency.

Robotics has been a game-changer in industries that require precision, speed, and accuracy. From assembling complex components in electronics manufacturing to welding in the automotive industry, robots are taking over tasks that were once labor-intensive and prone to human error. The use of collaborative robots, or cobots, is also on the rise. These robots work alongside human workers, complementing their skills and taking on dangerous or repetitive tasks, thus improving workplace safety.

Leading companies like Siemens and General Electric have embraced robotic systems, integrating them into their production lines to achieve higher levels of productivity. These systems allow for continuous production, 24/7 operation, and faster turnaround times, giving companies a competitive edge in the global market.

The concept of smart factories is closely tied to the Fourth Industrial Revolution, or Industry 4.0, which refers to the fusion of physical and digital technologies. In smart factories, every machine, device, and system is interconnected, allowing for seamless communication and coordination. This connectivity enables factories to operate autonomously, adjusting production processes in real-time based on data-driven insights.

For example, in the automotive industry, companies are using smart factory technologies to streamline the production of electric vehicles (EVs). Factories equipped with advanced robotics and automated systems can produce EVs more efficiently, reducing costs and accelerating the time-to-market.

Sustainability is another driving factor behind the adoption of automation and robotics in manufacturing. By optimizing production processes, these technologies help reduce energy consumption and waste. 3D printing, or additive manufacturing, is one such innovation that is gaining traction. It allows manufacturers to produce components on demand, reducing material waste and minimizing the environmental impact of traditional manufacturing methods.

Robotics also plays a role in making manufacturing more environmentally friendly. For instance, robots are being used in industries like agriculture and food processing to sort, pack, and process products with minimal waste. Additionally, automation can help companies adhere to stringent environmental regulations by ensuring precise control over resource consumption.

Despite the many benefits, the widespread adoption of automation and robotics presents some challenges. One major concern is the potential displacement of human workers. While robots can handle repetitive tasks, there is a growing need for highly skilled workers who can operate and maintain these automated systems. This shift is leading to the demand for upskilling and retraining the workforce.

However, the long-term opportunities are vast. As more industries adopt these technologies, there will be a greater need for expertise in robotics engineering, AI development, and data analytics. Educational institutions are also recognizing this shift, offering specialized courses to prepare the workforce for the future of manufacturing.

As automation and robotics continue to advance, the possibilities for smart factories are endless. In the coming years, we can expect to see more industries adopting these technologies to improve efficiency, reduce costs, and enhance sustainability. Innovations such as autonomous machines, AI-driven robotics, and advanced analytics will further drive the evolution of manufacturing, enabling industries to produce higher-quality products faster and at lower costs.

Moreover, the integration of 5G technology in industrial environments will enhance communication between devices, enabling faster and more reliable data transmission. This will further accelerate the adoption of smart factory technologies, allowing companies to remain competitive in an increasingly digitized world.

Automation and robotics are revolutionizing the industrial and machinery sectors, driving the shift toward smart factories and sustainable production methods. As these technologies continue to evolve, they will play a critical role in shaping the future of manufacturing, offering unparalleled efficiency, precision, and innovation.